Lubricant v.s Grease

Lubricant:Under high-speed and high-temperature conditions, lubricant can be used when grease is not applicable. Through the circulation of lubricants, a large amount of heat can be released.

Viscosity is an important characteristic of lubricant.Viscosity affects the fluidity of the lubricant and the thickness of the oil film formed between the friction surfaces. The viscosity of the lubricant when the bearing is operating is generally 12-15 cst. The higher the speed, the lower the viscosity should be selected, and the heavier the load, the higher the viscosity should be selected. ommonly used lubricants include mechanical oil, high-speed mechanical oil, turbine oil, compressor oil, transformer oil, cylinder oil, etc.

When applying lubricant to bearings, the most important thing is to select a suitable lubricant according to the using conditions. If the viscosity is too low, the oil film will break easily, which will cause abnormal wearing and burnout of the bearing. If the viscosity is too high, there will be increased torque, power loss, and abnormal rise in temperature. Generally, the higher the load, the higher the viscosity of the lubricant. Comparably, higher rotation speed requires lower viscosity.

|

Working temperature of the bearing ( °C )

|

dn value

|

ISO viscosity level of the lubricant (VG)(VG)

|

Applicable bearing

|

|

Normal load

|

Heavy load or shock load

|

|

-30 ~ 0

|

Range of permissible rotation speed

|

22 32

|

46

|

All

|

|

0 ~ 60

|

Below 15000

|

46 68

|

100

|

All

|

|

15000 ~ 80000

|

32 46

|

68

|

All

|

|

80000 ~ 150000

|

22 32

|

32

|

|

Excluding thrust ball bearing

|

|

|

150000 ~500000

|

10

|

22 32

|

Single row radial roller bearing

Cylindrical roller bearing

|

|

60 ~ 100

|

Below 15000

|

150

|

220

|

All

|

|

15000 ~ 80000

|

100

|

150

|

All

|

|

80000 ~ 150000

|

68

|

100 150

|

Excluding thrust ball bearing

|

|

150000 ~500000

|

32 46

|

68

|

Single row radial roller bearing

Cylindrical roller bearing

|

|

100 ~ 150

|

Range of permissible rotation speed

|

320

|

All

|

|

0 ~ 60

|

Range of permissible rotation speed

|

46 68

|

Automatic spherical roller bearing

|

|

60 ~ 100

|

Range of permissible rotation speed

|

150

|

※ dn value = Bearing center distance (mm) x rotation speed (rpm).

※This table is a lubricant selection guide based on JIS K 2001 industrial lubricant viscosity classification.

※Information shown in this table is a lubricant selection guide for mist lubricant or circulation lubricant..

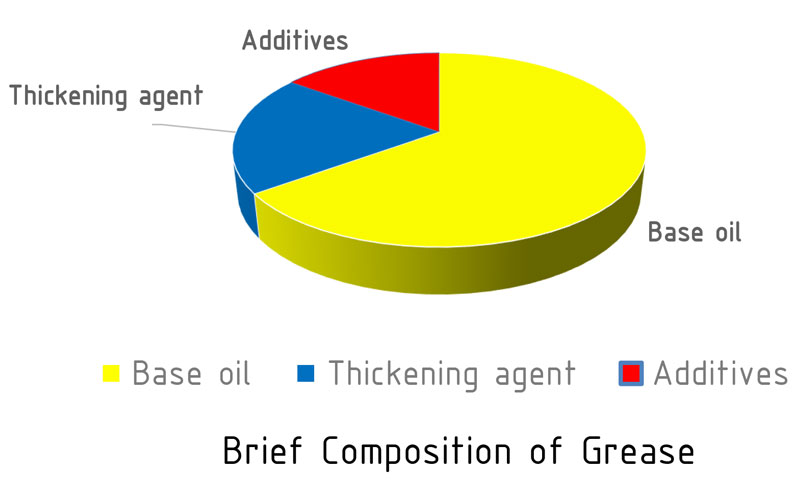

Grease:A lubricant composed of

base oil, thickening agent, and additives.

A grease that is suitable for the using conditions of the bearing shall be selected before use. The performance of the grease varies due to differences in trademarks. Please pay attention when selecting.

Commonly used bearing greases include calcium grease, sodium grease, calcium-sodium grease, lithium grease, aluminum grease, and molybdenum disulfide grease. The amount of grease applied to bearings is preferably 1/2 to 1/3 of the internal space of the bearing, which should be reduced to 1/3 at high speed. Excessive grease tends to increase the bearing temperature during operation.

Advantages of Selecting of Grease:

・Convenient – During manufacturing, bearings are pre-sealed with grease and do not require maintenance.

・Low cost - Reduces the number of mechanical parts and installation procedures when using sealed bearings.

・Grease is easier to handle compared to lubricants.

・The grease itself also has a sealing effect to prevent foreign matter from entering the internal space of the bearing.

When the bearings bought is of open type or with single-sided covers, you may need to apply the grease in most cases.

The amount of grease applied at this stage should not be too much, excessive grease will result in moment increase, power loss, and temperature rise due to stirring heat. The best-recommended amount of grease to apply is:

・When the rotation speed is less than 50% of the permissible rotation speed, the amount of grease applied shall be 1/2 to 2/3 of the internal space of the bearing.

・When the rotation speed exceeds 50% of the permissible rotation speed, the amount of grease applied shall be 1/3 to 1/2 of the internal space of the bearing.

|

Using conditions

|

Grease

|

Lubricant

|

|

Temperature

|

Cannot be used in high temperature environment

|

Can be used in high temperature environment (circulating cooling)

|

|

Speed

|

Low speed to moderate speed

|

Can be used in high speed

|

|

Load

|

Below moderate load

|

Applicable to high load

|

|

Structure and maintenance of bearing housing

|

Simple

|

Complicated, need to pay attention to oil leakage

|

|

Concentrated apply of lubricant

|

Possible

|

Easy

|

|

Filter foreign matter

|

Impossible

|

Possible (circulating filtration)

|

|

Rotation impedance

|

High

|

Low (must maintain an appropriate amount of lubricant)

|

Copyright © 2025 YJPB | A 25-year specialist for high-end bearings in large dimensions All Rights Reserved.